Three-phase electric motors with external rotor

Three-phase electric motors with external rotor

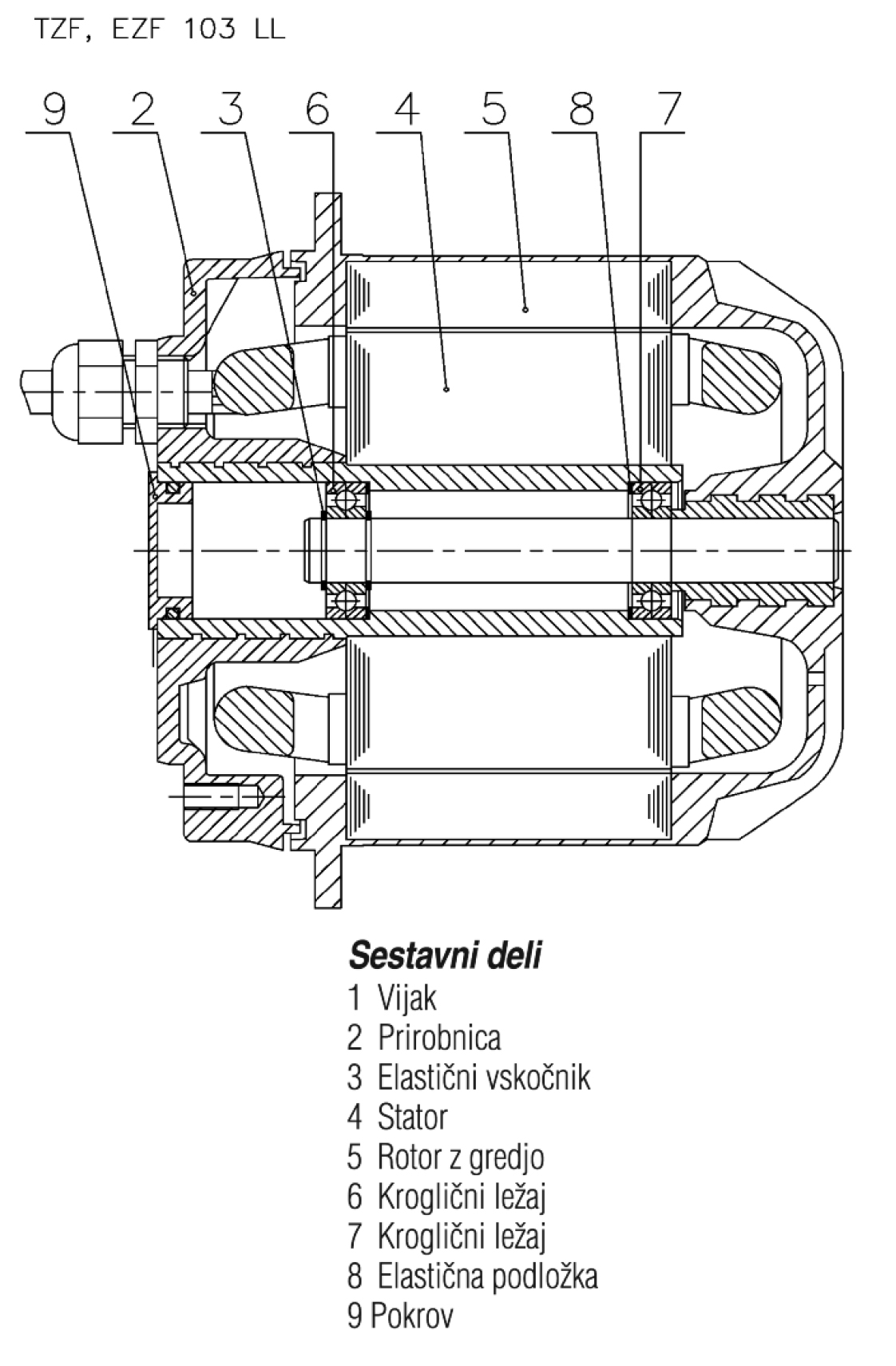

Description

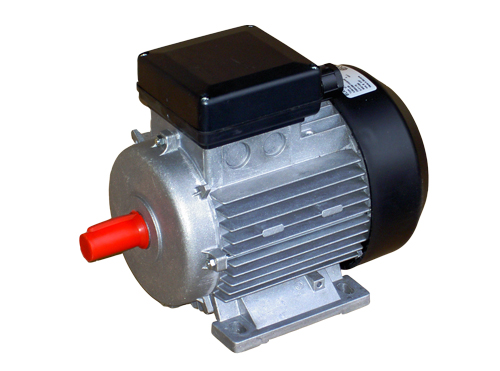

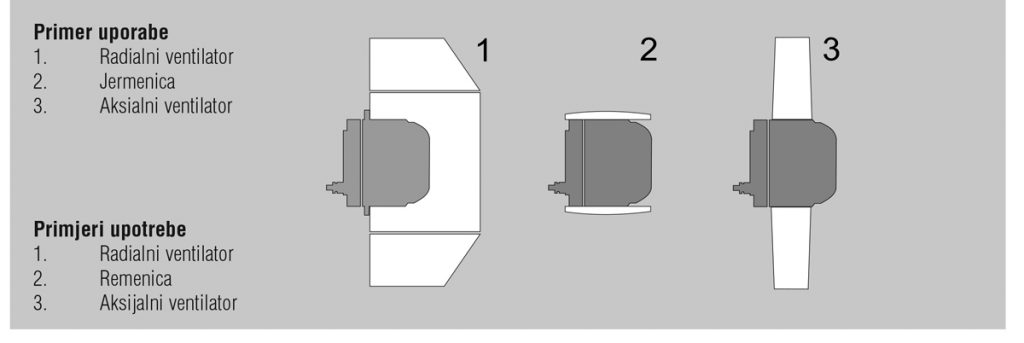

We are increasingly using electric motors with an external rotor to drive the fans. These are special electric motors that can be attached directly to the fan. The advantages of these engines are the following:

– lower consumption of installation space,

– indirect drive of the fan with the pulley is eliminated,

– possibility of regulating the speed of rotation in the range from 0-100% with satisfactory cooling and coordination of the characteristics of fans and motors (with the help of devices for regulating the speed of asynchronous electric motors).

Electric motors with an external rotor can also be used to drive grinding and polishing machines, oil or gas burners, centrifuges, and reducers.

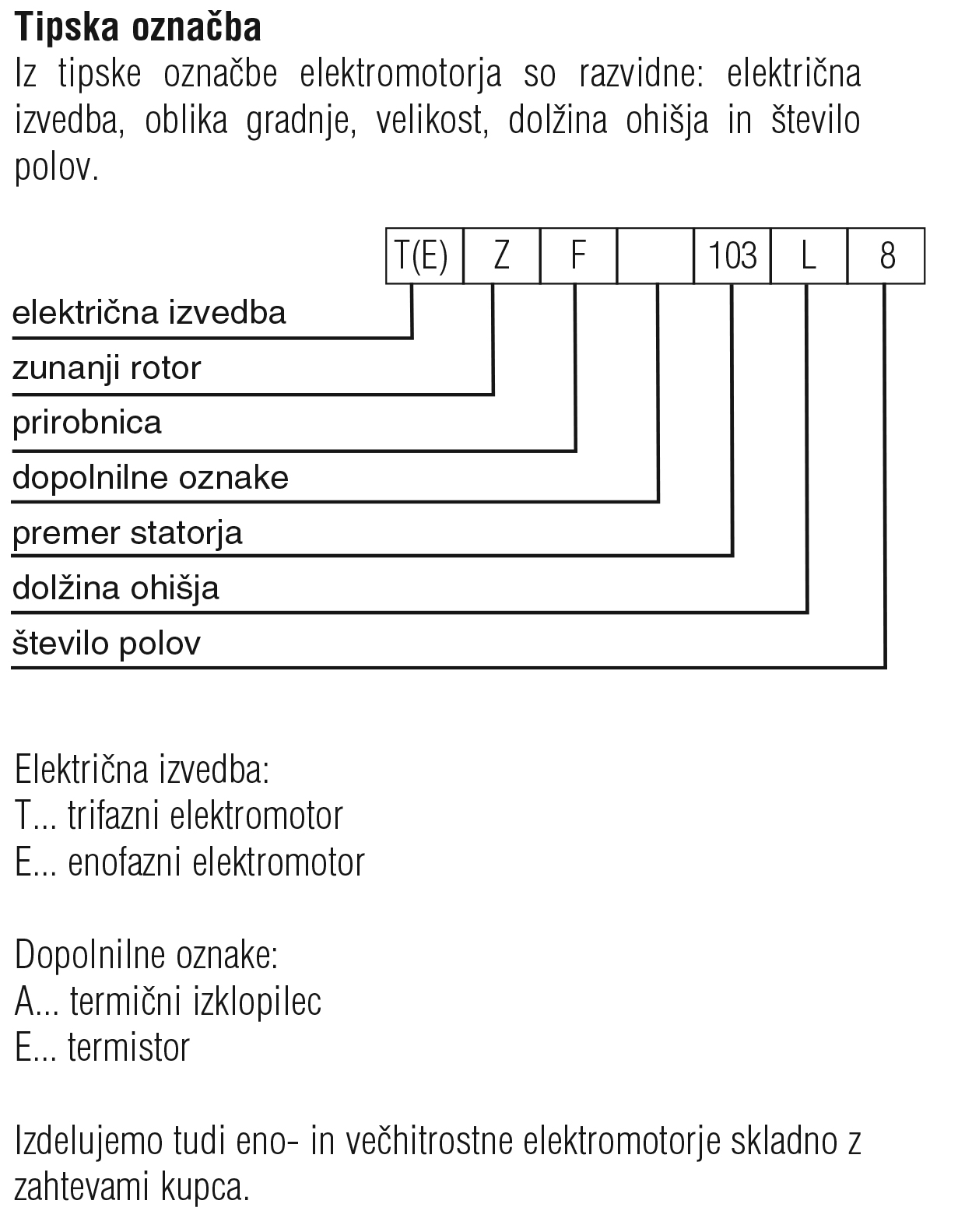

Electrical version

Description

Voltage and frequency

Standard three-phase electric motors are built for connection to the Y 400V/50Hz or Y 460V/60Hz network, except for TZF 160 L4 electric motors which are built for connection to the D 400V/50Hz or D 460V/60Hz network. Standard single-phase electric motors are electric motors built for connection to the 230V/50Hz network. The permissible deviation from the rated voltage and frequency is ± 10%. We also make electric motors for other voltages and frequencies by special order.

Insulation class

The insulation of electric motors corresponds to insulation class F according to IEC Publ. 34 or Publ. 85 and DIN VDE 0530/T.1. The heating of the electric motor windings at the rated powers given in the tables corresponds to insulation class B.

Thermal protection

In most cases, bimetallic thermal triggers are sufficient for thermal protection of motors. For more difficult motor operating conditions, such as speed control, occasionally elevated ambient air temperatures, several starts or installation in devices with poor cooling conditions, we recommend motor protection with thermal switches or thermistors which are installed in the windings only at the request of customers.

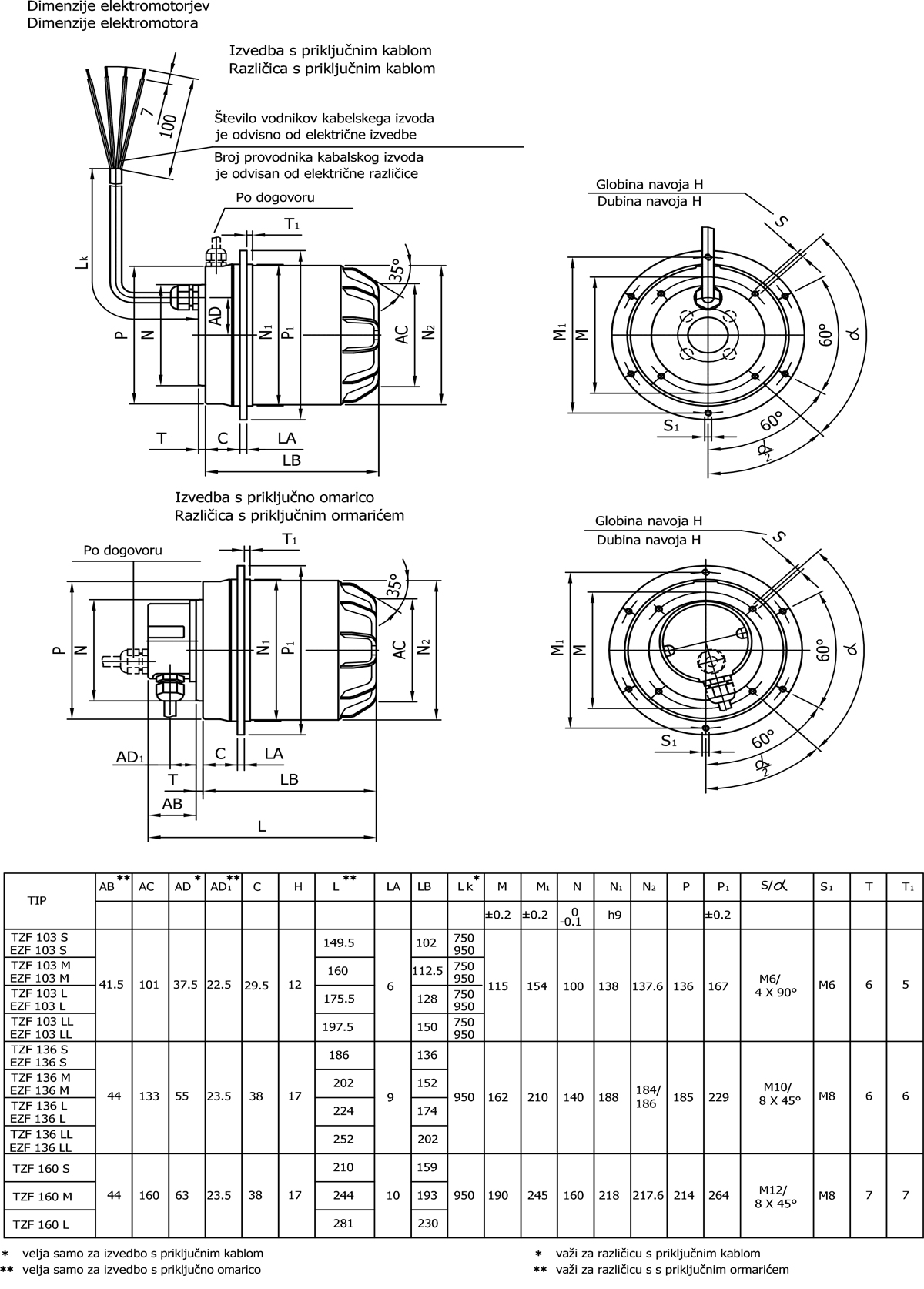

Engine connection

The motors are equipped as standard with a multi-core thermally resistant connection cable. They can be equipped with a terminal box on special request. The cable length (Lk) is given in the dimension table for individual types. On special request, it is possible to obtain a cable with a length that deviates from the data in the table and outlets laterally from the flange.

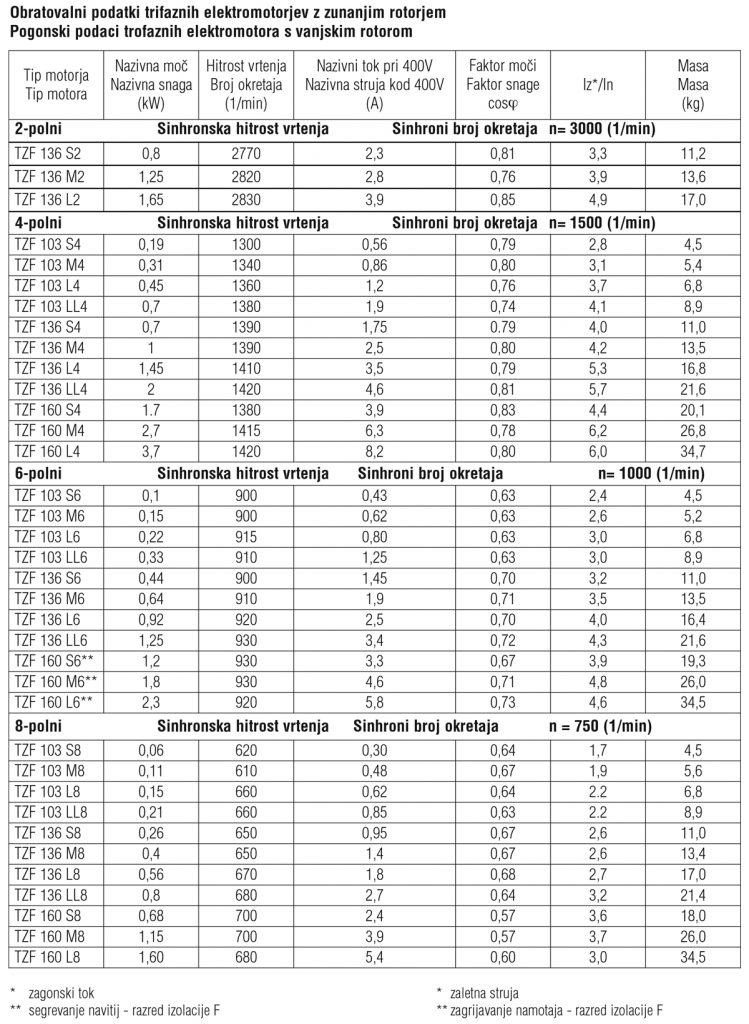

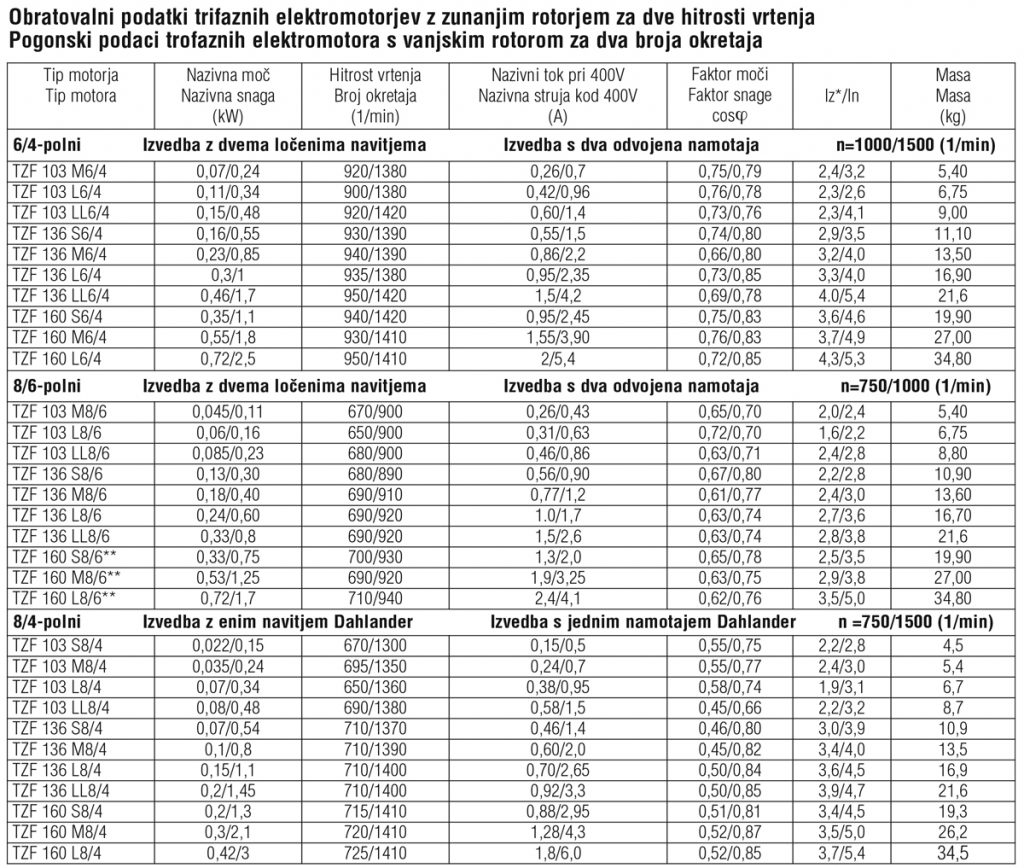

Rated power

The rated powers given in the table are the powers emitted by the motors via the flange on the rotor at continuous load, rated voltage and frequency, with ambient temperature not exceeding 40oC and altitude of up to 1,000 m. Motors can also be loaded with increased power during intensive cooling, but only if the heating of the motor winding is measured beforehand.

Implementation of single-phase motors

All single-phase electric motors are made with a permanently connected, i.e. drive paper or metal-paper capacitor. The starting torques of these motors are relatively small and amount to 60% of the rated torque. The motors are therefore suitable for driving fans and other drives where high starting torques are not required.