PC submersible drainage sump pumps for greater depths

PC submersible drainage sump pumps for greater depths

Description

PC submersible borehole or underwater pumps for greater depths are intended for pumping clean water from earth holes or deep wells, where the water is located at great depths. They are suitable for supplying residential settlements and industrial facilities with drinking water. All pumps can also be used in conventional deep wells. By pumping water from wells near construction sites, the level of the groundwater can be lowered. The water temperature must not exceed 30°C.

The pumps are suitable for supplying residential and industrial buildings with water. They are often used as part of irrigation systems. By operating the pumps in the borehole system, we can lower the groundwater level in the selected area. All pumps made with bronze housings are also suitable for pumping mineral water. When equipped with special motors, they can also be used to pump seawater.

Technical characteristics

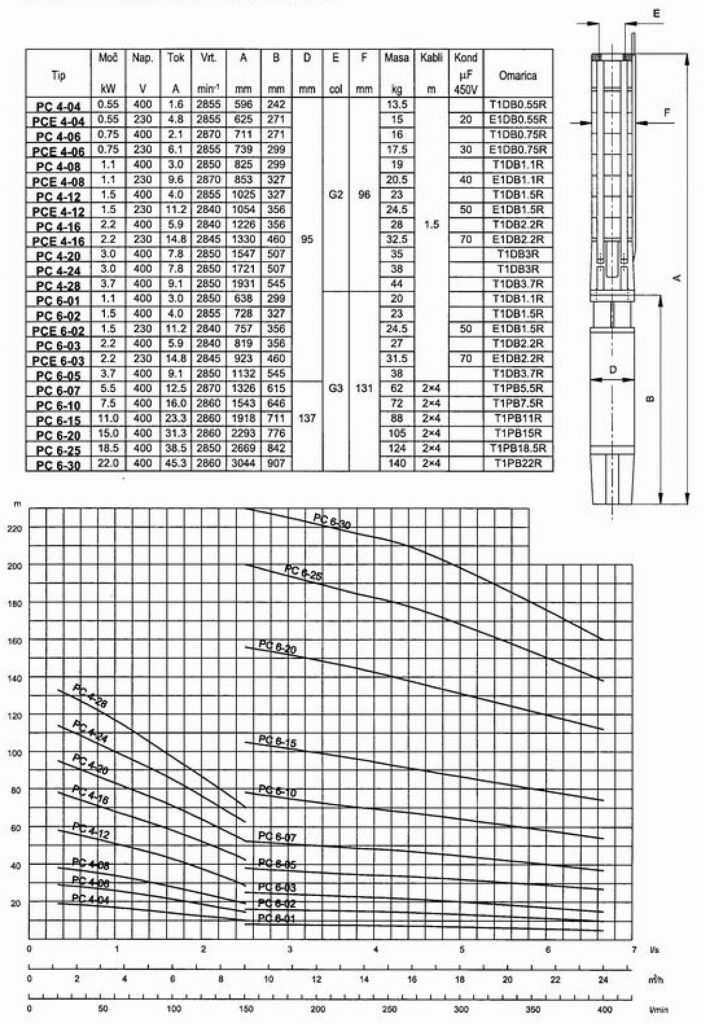

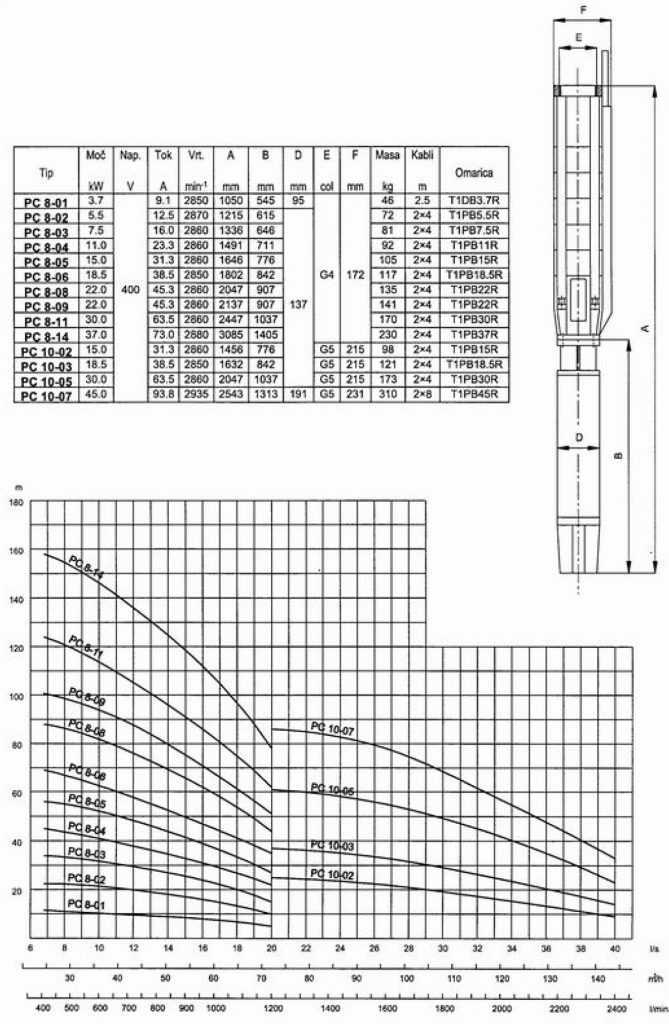

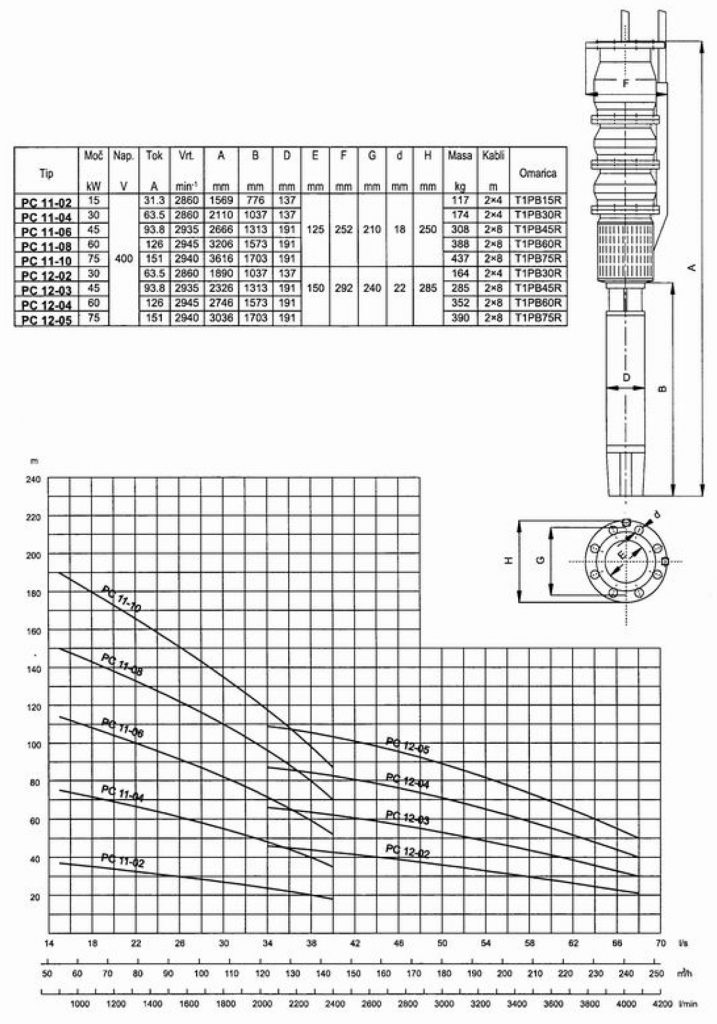

Flow: from 30 to 4100 l/min

Lifting pumping height: up to 230m

Engine power: 0.55 ÷ 75kW

Power supply: 1-phase (230V) or 3-phase (400V)

Medium temperature: from 0°C to + 30°C

Ambient temperature: from 0°C to + 40°C

Suction height: up to 200m

Weight: 13 – 390kg

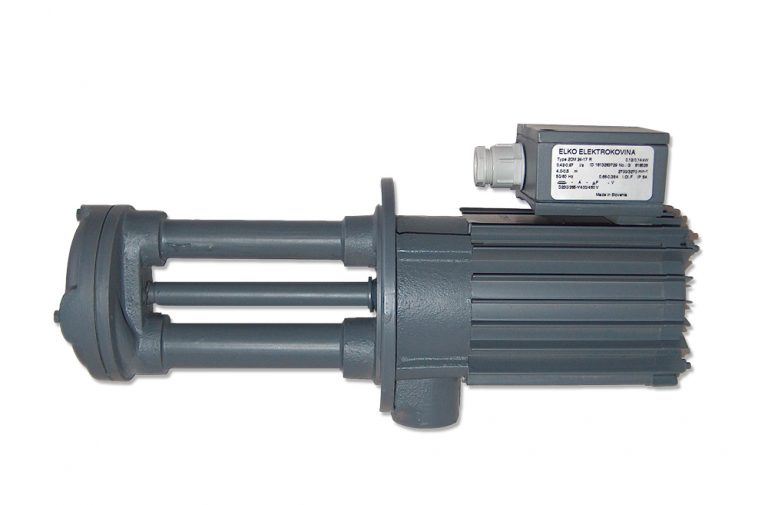

The submersible borehole pump for greater PC depths consists of a multi-stage pump section and a submersible electric motor in the wet version. The pump section shaft and the electric motor shaft are connected by a rigid coupling. The pump can only be operated in a vertical position. The motor is mounted on the lower part of the pump, its axial bearing withstands the influence of pressure and weight of the rotating parts. The pump section has an integrated suction basket, which prevents larger particles from entering the pump, and a non-return valve. The characteristics of the pumps are given for the whole set, and they include the losses of the integrated elements.

Electric motors with the power of up to 37 kW are made with resin-coated windings, while larger electric motors have wet windings with adequate conductor insulation. On request, electric motors from 5.5 to 37 kW can also be made with wet windings which can be repaired by rewinding. All electric motors of 5.5 kW and more are designed for a Y/Δ start and have 2 connection cables each. The electric motors are equipped with cables as shown in the table. We include insulating material with the pumps for the making of waterproof cable extensions. We also offer control cabinets for all pumps, which are equipped with probes for protection against dry running of the pumps and with bimetal protection against overloading of the electric motor. The pump is controlled by a connected pressure switch or float switch. Pump control cabinets with single-phase motors have permanently connected drive capacitors.

The pump can be installed in a borehole or a well by hanging on a pressure pipe. During operation, the water cools the electric motor, so the movement of water next to the motor at a speed of at least 15 cm/s must be ensured. The pump must be submerged so that it operates reliably without cavitation. The dynamic water level in the well should be at least 0.5 m above the pressure connection of the pump. The operating point of the pump must be selected so that the dynamic level in the hole is not compromised and the number of starts does not exceed 20 starts per hour.

Purpose of use

for drinking water management

domestic use for the care of single-family houses

supply of facilities with higher water consumption

for irrigation systems

farms

pool technology

industrial purposes

plumbing systems

watering and irrigation systems

groundwater level monitoring

fire protection systems

mining industry